| Model steel coil pipe production line | ||||||||||||||||||

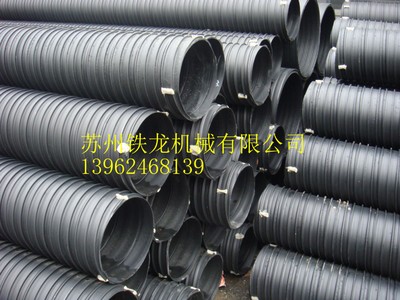

Model steel coil tube is made of steel-plastic composite profiled strip by the spiral wound (lap surface extrusion welding) welding, its high ring stiffness, the lining is smooth level off, the specification of DN200 - DN3000mm. This kind of tubing corrosion resistance, light quality, easy installation, large flow, and the advantages of long service life (50 years), alternative energy materials (cement, iron, ceramics, etc.) production of pipe material, environmental protection green products. Model steel coil pipe production line adopts advanced modular design, equipment operation more simple. Adopt high efficiency single screw extruder, low energy consumption, high output. PLC intelligent control, stable and reliable, high degree of automation. Developed a unique model steel composite technology, strip and tube production at the same time, a molding, steel belt compound in HDPE completely, no bubble, no loss, corrosion from the other media. Configure the independent research and development Model steel coil tube is made of steel-plastic composite profiled strip by the spiral wound (lap surface extrusion welding) welding, its high ring stiffness, the lining is smooth level off, the specification of DN200 - DN3000mm. This kind of tubing corrosion resistance, light quality, easy installation, large flow, and the advantages of long service life (50 years), alternative energy materials (cement, iron, ceramics, etc.) production of pipe material, environmental protection green products. Model steel coil pipe production line adopts advanced modular design, equipment operation more simple. Adopt high efficiency single screw extruder, low energy consumption, high output. PLC intelligent control, stable and reliable, high degree of automation. Developed a unique model steel composite technology, strip and tube production at the same time, a molding, steel belt compound in HDPE completely, no bubble, no loss, corrosion from the other media. Compatible with winding cage is configured with independent research and development, strong compatibility, large-diameter pipe production speed is fast, stable quality, two production lines can be full of DN200 - DN3000 diameter series pipe production. Polyethylene plastic coil pipe complete sets of production equipment is composed of plastic composite strip production line and pipe winding line. Plastic composite strip rolling mill production line of steel belt, welding machine, straightening machine, high frequency heating mechanism, single screw extruder, strip operation control cabinet, aluminum extrusion die, strip shape mould, finalize the design, composition of tractor. Coil production line by the pipe material operation control cabinet, electrode materials, machine, winding machine, hot air gun heater of cage, pipe cutting saw, pipe belt conveyor. Plastic composite strip using a unique extruder molding production process, make the steel strip after straightening machine is flat and level, derusting and high frequency heating into the strip of the single screw extruder extrusion die with a complete melting of high density polyethylene two kinds of material structure of the composite, and the strip shape and strip is formed after calibrating bench to finalize the design, cooling, strip by the winding pipe. Composite molding plastic coil tube after have the characteristics of the structure size stability, uniform coating level off. The compatibility of winding cage, strong compatibility, large-diameter pipe production speed is fast, stable quality, two production lines can be full of DN200 - DN3000 diameter series pipe production. Polyethylene plastic coil pipe complete sets of production equipment is composed of plastic composite strip production line and pipe winding line. Plastic composite strip rolling mill production line of steel belt, welding machine, straightening machine, high frequency heating mechanism, single screw extruder, strip operation control cabinet, aluminum extrusion die, strip shape mould, finalize the design, composition of tractor. Coil production line by the pipe material operation control cabinet, electrode materials, machine, winding machine, hot air gun heater of cage, pipe cutting saw, pipe belt conveyor. Plastic composite strip using a unique extruder molding production process, make the steel strip after straightening machine is flat and level, derusting and high frequency heating into the strip of the single screw extruder extrusion die with a complete melting of high density polyethylene two kinds of material structure of the composite, and the strip shape and strip is formed after calibrating bench to finalize the design, cooling, strip by the winding pipe. Composite molding plastic coil tube after have the characteristics of the structure size stability, uniform coating level off. | ||||||||||||||||||

| 上一页:SGB2000 large diameter coil pipe production line 下一页:HDPE plastic coil pipe production line | ||||||||||||||||||

|